This Le Cheminant Master Mariner was certainly in need of some attention.

(Click pictures to enlarge)

Regular readers may recognise this model as I restored one around three years ago. I’m always impressed by how well this style of watch responds to some TLC so I thought it couldn’t hurt to write a post about another one.

In the previous article I covered the history of Le Cheminant and similar models from other manufacturers (that post here) so let’s get right down to business…

As you can see above the watch had its fair share of issues. The lume had deteriorated throughout, the crystal was cracked around the top edge, the bezel had lost most of its paint and the watch had a poor fitting crown and stem. Added to that, the watch was not running and would wind forever, a sure sign that the mainspring was broken.

Opening the watch revealed a Valjoux Cal. 92, the highest quality calibre that is found in this style of watch and it was in decent cosmetic condition too with just a hint of tarnish here and there. A good start.

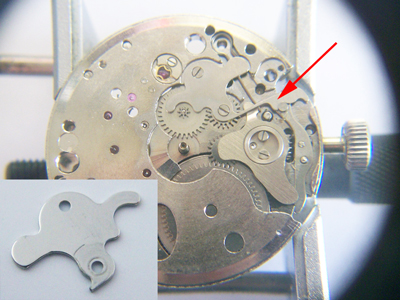

It wasn’t long however before the problems started to arise, the first being the set lever spring which had snapped off meaning that the watch would not click out securely into the time setting position. Thankfully the majority of parts can still be sourced for the Valjoux 92 so this one was an easy fix.

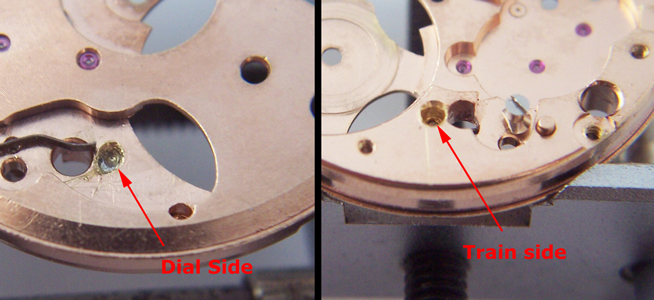

The next problem however was a bit more serious. The last watchmaker to work on the watch had obviously snapped off the head of the click screw on the dial side of the movement (the click stops the mainspring from unwinding). In an attempt to remove the broken shaft, which can be troublesome at the best of times even with the right tool, he had drilled through the mainplate from the train side in an effort to drive out the broken shaft.

This had obviously been unsuccessful as the shaft was largely still in place and doing so had trashed the threads in the mainplate. To make matters worse, rather than repair the damage properly, as a workaround, the replacement click screw had been superglued into the hole. A nasty surprise for the next watchmaker… ie. me!

In cases like this the correct way to repair this kind of damage is to drill out the entire damaged section of the plate and insert a brass bush of the same thickness as the mainplate, giving a stable platform in which to drill and tap a new hole for the screw.

With limited material left to work with this proved to be quite difficult as the position of the click screw has to be exact or the click will jam in the teeth of the ratchet wheel. Thankfully it all worked out successfully so with the movement serviced and back up and running properly it was on to the cosmetic work.

It was decided that the dial, hands and bezel pip should be re-lumed with a green lume as they would have been originally and the case was fully stripped down, cleaned, and given a light buff to restore the shine. The crystal and gaskets were replaced and a new crown and stem were ordered after which the watch could be rebuilt.

The last thing to do was to remove the old paint and refresh the bezel markings. There was some discussion with the owner regarding the choice of colour scheme. On close inspection of the remaining paint fragments it appeared that originally the numbers were black and the minute track was red all the way around, so we went with that.

Here is the watch all finished up. Another great transformation from a pretty rough starting point.

Rich.

** Many thanks to Richard Whittaker for letting me feature his watch on the blog. **