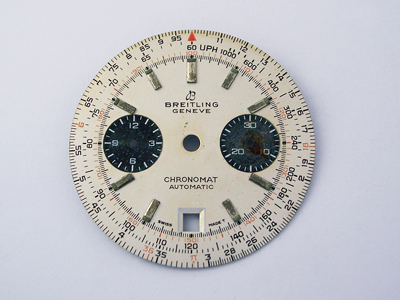

Here’s a watch that’s tricky to hide under a shirt cuff, the Breitling Chronomat Automatic.

(Click pictures to enlarge)

Announced by Breitling in 1941 and brought to market in 1942, the Chronomat was Breitling’s first watch (and the second ever) to feature a slide-rule bezel.

Although a bit ‘old school’ today, a slide-rule bezel was useful for pilots, scientists and engineers to perform calculations, conversions and arithmetic before the advent of calculators and GPS. For an in-depth tutorial on how to use a slide-rule bezel, here’s an excellent video on the subject.

The Chronomat format proved popular, so much so that the model remains in Breitling’s model range today (albeit without a slide-rule!)

There are too many details on the Chronomat and its various iterations over the years to cover here, but this excellent two-part post by altro on the WatchUSeek forum should give you all the information you need.

For the first few decades, the Chronomat was powered almost exclusively by the manually wound Venus cal. 175, but fast forward to the late 1960’s and the model in this post homes into view, the Ref. 1808 featuring Breitling’s first automatic chronograph calibre, the cal. 12.

The story about the collaboration between Breitling, Heuer, Hamilton-Buren, and Dubois Dépraz to produce -arguably – the first automatic chronograph is well known (more information here), and having written about the sibling to this watch in the past, the Cosmonaute Ref 1809, I’ll skip over the technical details this time and focus on the specific issues with this watch.

If you looked closely at the first picture, you’ll have noticed that all was not as it should be with the dial and hands, which had significant rust staining. Generally speaking, this is an indication that a seal has failed and the watch has had enough water inside for rust to creep through the movement and out onto the dial, so I was expecting the worst.

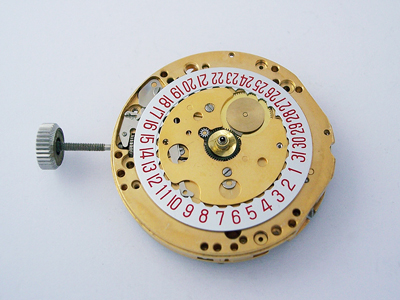

However, on opening the caseback, I was pleased to find the movement in relatively good condition, at least on initial inspection.

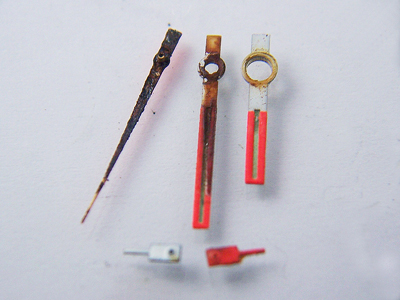

I removed the dial and hands to start the movement service and they weren’t exactly a pretty sight, but more on that later…

On removing the dial, I was surprised to find that there was no sign of moisture on the dial side of the movement either, even the date ring, which is one of the most delicate parts, was in perfect condition.

So, what caused the rust damage here then? In short, condensation.

When a watch has a small amount of moisture inside, condensation forms of the coolest part of the watch, which when being worn is typically across the underside of the crystal. When the watch cools, unless there is a lot of moisture in the watch and it forms large droplets, the water vapour will then ‘move’ and re-form on surfaces cooler than the crystal (which is why it’s not uncommon to think that the moisture has ‘magically disappeared’), in this case onto the dial markers and hands.

The owner of the watch bought it in this condition, so the history is unknown, but I’m assuming that the previous owner wore the watch, saw the condensation on the crystal and set it to one side for attention later, not realising that droplets had formed between the dial and hands. Rust then formed over time, resulting in staining.

The hands could be addressed, but the dial was more difficult. The loose rust debris could be removed and the dial markers improved a little, but the staining on the minute subdial was a problem.

Wetting the area to try and lift the stain is one of the few options available, risky, but it worked this time. For most part anyway, but as the staining was covering the ’10’ numeral in this case, a decision was made to leave that area as-is – a discoloured 10 is better than no 10 at all!

The hour, minute and subdial hands were beyond repair and so were stripped, painted and relumed, but chronograph sweep hand was salvageable. The rust was removed from the back of the hand and the original paint carefully cleaned. A few small imperfections remain, but aren’t bad enough to warrant a total repaint, and it fits the overall patina of the watch.

The rest of the movement service was straight-forward with no unexpected surprises, so with the case and bracelet cleaned and the crystal was polished, the watch was rebuilt to fight another day.

Rich.

** Many thanks to Niclas for letting me feature his watch on the blog. **

Hi Richard,

I have a 1808 Breitling Chronomat Automatic. Needs work.

Anybody in the US that you would recommend. I am outside Reno Nevada on the west coast!

Best,

Bjorn