Produced between 1972 and 1977, the cal. 7016A was one of Seiko’s most technically interesting calibres. Packed with functionality, it offers time(!), a 12 hour flyback chronograph, automatic winding, date and bi-lingual day display, both with quickset.

What makes this calibre unique in the Seiko range is that both chronograph registers share the same subdial, consequently watches with this calibre are often referred to as a “2 in 1” chronograph…

(Click pictures to enlarge)

In terms of specifications the 7016A is a 17 jewel calibre that beats at 21,600bph (6 beats/sec). Sizewise, it is 27mm in diameter and at only 6.4mm high, it was the world’s thinnest vertical clutch chronograph until F. Piguet released the 5.5mm high cal. 1185 in 1987.

With the winding rotor removed, you can see that it shares the same ‘magic lever’ winding mechanism as the rest of the 70xx series calibres…

Although the most complex, with 17 jewels, the 7016A has the least number of jewels in the calibre series; the 7015 and 7017 calibres both have 21 jewels (additional cap jewels on the third and escape wheel pivots), and the 7018 has 23 jewels (two more jewels for the minute recording wheel). The jewel positions are typical of any 17 jewel Seiko automatic calibre in that all but one of the train wheel pivots are jewelled, and two jewels are used in the winding mechanism.

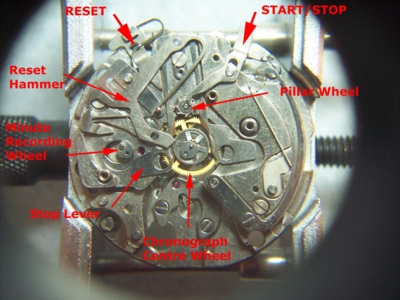

Removing the barrel and train wheel bridge reveals the chronograph mechanism, which apart from the minute recording wheel, is the same as the cal. 7017A that I worked on recently…

The chronograph operation is identical: On pressing the start/stop button, the operating lever pushes the pillar wheel forward which prises apart the stop lever, allowing the clutch ring to drop onto the clutch plate on the fourth wheel below. The second hand starts to move as it is mounted on the axle of the chronograph centre wheel, which extends through the movement and out onto the dial.

On pressing the start/stop button again the reverse happens. The pillar wheel is pushed forward once more, releasing the pressure from the stop lever which then retracts, contacts the clutch ring again, and raises the mechanism from the clutch plate below.

When the reset button is pressed, the reset hammer moves across and rotates both the minute and second chronograph hearts back to zero from any position.

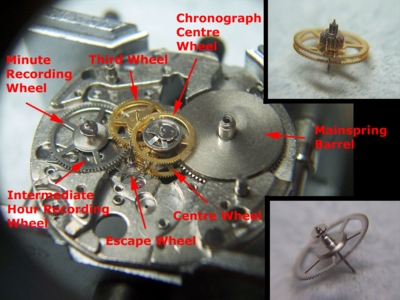

With the chronograph bridge removed the wheel train is uncovered, and this is where things start to get interesting…

As you can see in the picture, the wheel train is very compact. Rather than redesign the main plate to accommodate intermediate wheels and levers to operate the registers, Seiko chose to make changes to the wheels themselves.

The upper inset picture shows the third wheel which consists of two separate wheels on a single axle, each driven by a different pinion. The upper gear behaves just like a regular third wheel in that it transfers power from the centre wheel to the fourth wheel. The lower gear is used only when the chronograph is engaged, transferring power from the chronograph centre wheel to the minute recording wheel.

The lower inset picture shows the minute recording wheel, the axle of which extends through the movement and out onto the dial (the minute register is mounted on this axle). Inside the central housing is a friction spring used during reset. Beneath the minute recording wheel you can see the intermediate hour recording wheel which transfers power to the hour recording wheel on the dial side of the movement.

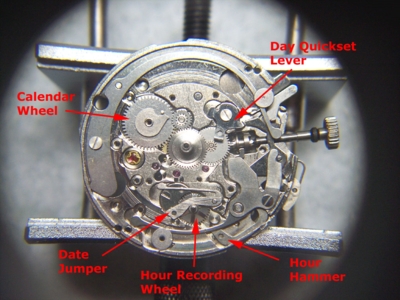

Turning the movement over and removing the date dial guard reveals the dial side components…

The layout on this side is very similar to all other 70xx series calibres except that additional components for hour recording have been added around the date jumper. With the majority of the dial side components removed you can see these additions more clearly…

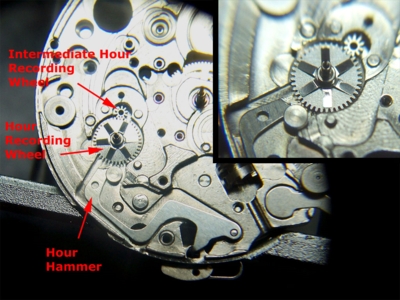

Without the cover plate you can see that the pinion from the intermediate hour recording wheel comes through onto the dial side of the movement and meshes with the hour recording wheel (on which the hour register hand is mounted). Also pictured is the reset hammer which moves across and under the hour recording wheel, contacting a chronograph heart on its underside.

Like the other chronograph registers, the hour recording wheel also has a friction spring (inset). These friction springs are the key to the reset and flyback operations.

Unlike the wheels in regular calibres, the gears of the chronograph register wheels are not fixed on the axles. All three wheels consist of two distinct sections, a gear and an independent central axle. The friction spring is attached to the axle and provides the tension between the two sections to make them rotate together when the chronograph is engaged.

In all three cases the chronograph heart is also fixed to the central axle, so when the reset button is pressed, the reset hammer contacts the chronograph heart, overcoming the pressure from the friction spring and rotates the central axle back to zero. The wheels themselves do not turn during reset. When the reset button is released, the friction springs resume their job and the two sections rotate together once more.

The cal. 7016A is a very slick design and is often compared with the cal. 6138, though they are technically very different. In operation too, the cal. 7016A is slightly different as the minute register moves constantly, it does not jump from one minute to the next as it does in the cal. 6138.

With clever ‘wheel technology’ and using fewer parts, the cal. 7016A is more compact than the cal. 6138, and has an additional flyback feature. But does that make it better?

That’s for you to decide…. though it’s probably best just to have one of each!

Rich.

Nice info Richard they are a fine looking Chrono & thanks for the great technical info>>

Rick

I’ve just bought a Seiko with this movement in it – can’t wait for it to arrive! The photos I’ve seen of it show a fairly clean dial but a dirty movement. Apparently it works though!