Another Zenith on the blog, this time a vintage Defy.

(Click pictures to enlarge)

The Defy is a long serving model in the Zenith range (the name being an anglicization of the French word “Defi” meaning “Challenge”) and the subject of this post is the first Defy model which was introduced in 1968 at a time when Zenith were looking to break into the sports watch market.

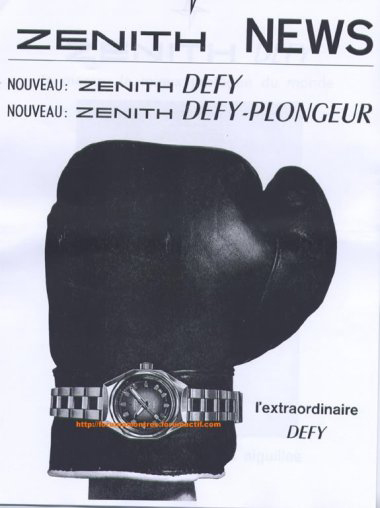

With a screw down crown, hardened mineral crystal, water resistance to 300 metres and built-in shock absorption, it’s clear that the watch pulled no punches in terms of toughness… a terrible segue into this advert there, apologies!

The first model was introduced with a choice of dial colours and additional Defy models were produced during the 1970’s in a variety of case designs.

Opening the watch reveals a Zenith cal. 2552 PC, an in-house 23 jewel automatic calibre with a beat rate of 21,600 bph. (Notice that around the movement is a rubber spacer which acts as the aforementioned shock absorber.)

Only the early watches were fitted with this calibre as from 1971 onwards it was replaced by the cal. 2562 PC and 2572 PC both of which had an increased beat rate of 28,800 bph. You may see “28 800” printed on the dial of some models to reflect this.

The watch arrived in running condition, but the gaskets had deteriorated into a black paste and judging by the condition of the oils, the movement hadn’t been serviced for quite some time.

While the movement showed no sign of corrosion, the gaskets had obviously been in poor shape for a long time as the dial and hands did show some deterioration due to moisture ingress; the lume had discoloured slightly (albeit not in an unpleasant way) and the hands were tarnished.

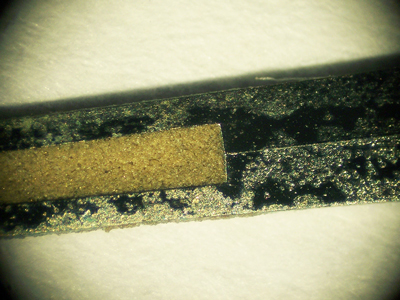

You’ll often see the word ‘tarnished’ associated with hands and dial markers on vintage watches and it generally refers to the plated surfaces having corroded. Under the microscope you can see that the top layer of the chrome plating has become pitted due to tiny droplets of water sitting on the hands for an extended period – effectively “eating away” the plated surface over time.

There isn’t really much that can be done to improve the finish once this has occurred as most hands are either chrome or gold plated and any attempt to polish out the pitting simply wears through what is left of the plating to the base metal underneath. The only solution is to have the hands re-plated, but that means losing the original luminous filling. In most cases it’s often best just accept the tarnish and polish the remaining plate as much as possible, and that was the preferred option here.

The movement was in good condition and it needed no more than a routine service, and the case too was still in good order and only needed an ultrasonic clean and light buff to restore the shine. The crystal however had a few scratches and chips around the edge which isn’t uncommon for this model as the crystal sits a long way above the bezel and even though hardened, is still susceptible to knocks and scrapes.

As the watch is long discontinued, finding original mineral crystals can be very difficult and often an acrylic aftermarket replacement is the only alternative, but even they can be difficult to source. Thankfully the owner of this watch tracked down a replacement crystal which made my job a little easier this time.

With the movement serviced and the new crystal and gaskets fitted, the watch could be rebuilt.

Rich.

** Many thanks to Francois Canters for letting me feature his watch on the blog. **