This Lemania Tg 195 chronograph arrived in a pretty sorry looking state.

(Click pictures to enlarge)

Made in the 1950’s this watch was issued to Swedish military personnel, as evidenced by three large crowns which can be found on the caseback of all Swedish military watches. There are two versions of the Tg 195 caseback; the earlier models have three small crowns (inset) and the later models have the three large crowns seen here (this watch was issued in 1957).

The watch can be found with four different dials too, all identical apart from the Tg 195 markings. The earliest watches had no Tg 195 at all, and subsequent watches were marked either “tg 195”, “Tg 195” or “TG 195”.

The meaning of the Tg 195 isn’t clear and there is little confirmed information to be found online, but the watch is often described as a ‘bomb timer’ and is said to have been issued exclusively to the Swedish Army bomb squad. The Tg part is thought to mean Tid Givare (“Giving Time” in Swedish) but the exact meaning of 195 is unknown. There may well be more information to be found through Swedish sources, but my Swedish isn’t all that it could be. 😉

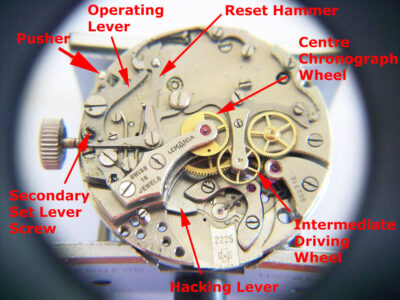

Underneath the caseback is a dust cover which when lifted uncovers a 16 jewel Lemania cal. 2225, derived from the Lemania cal. 2220 single pusher chronograph which I’ve described before (see here).

The calibre 2225 has a unique hacking mechanism added specifically for Swedish military requirements. When the pusher is pressed, the sweep second hand is reset instantly to 12 o’clock, the crown pops out to the time setting position, and the watch hacks.

Let’s have a closer look at how that works…

With the balance assembly removed you can see that under the balance wheel is a hacking lever with a thin wire on the end. When the pusher is pressed, the operating lever moves clockwise around the large pivot screw, moving the hacking lever backwards so that the wire arrests the balance. At the same time, the reset hammer moves across and disengages the intermediate driving wheel from the centre chronograph wheel. Under power from the large click spring, the reset hammer moves further across and contacts the heart on the centre chronograph wheel, resetting the second hand to zero.

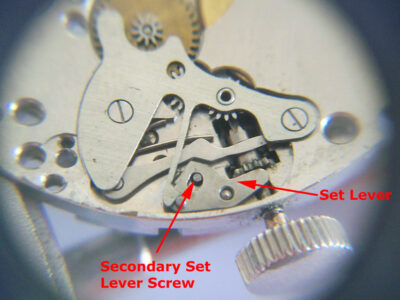

There is a second screw on the operating lever (marked secondary set lever screw in the picture above) which passes through the entire calibre and into the keyless works section on the dial side of the movement, emerging in a hole in the setting lever.

When the pusher is pressed this screw also moves the setting lever forward, forcing the stem and crown to pop out into the time setting position. The watch is now hacked and ready to be synchronised.

When the crown is pressed back in, the watch is restarted; the operating lever and reset hammer are returned to their starting positions on the train side of the movement, the hacking lever moves forwards releasing the balance, and the chronograph is re-engaged.

The watch was in pretty poor shape from a cosmetic perspective and out of the case it was clear to see that the dial and hands were in poor shape. The dial was covered in a layer of dirt, the lume on the numerals had crumbled to dust, and the hands were tarnished.

From such a rough starting point the results were never going to be perfect, but with all the old lume removed, the dial cleaned and the tarnish removed from the hands, things were much improved. As the numerals on the dial now matched the patina of the rest of the dial markings, a decision was made to leave them and just the re-lume the hands.

Another problem with the watch was the crown and stem. Although the original crown was included with the watch, the stem had sheared off flush with the crown, leaving a section of the stem still inside the crown. Soaking the crown in an alum solution for a week or so to ‘eat away’ the stem inside saved the original crown, but finding a replacement stem proved difficult as the stem is unique to this calibre.

While I could have made a new stem, it was more time/cost effective to modify a stem extender to increase the length of the stem by the required amount. The steel section just below the crown is the extender and an unmodified extender is included in the picture below for reference.

Aside from the problems with the crown and stem, the movement was in reasonable condition and just needed a service and some of the tarnished parts refinishing /polishing. Here’s the watch watch all back in one piece.

If anyone has any more information about the history of the Tg 195, it would be great to hear from you.

Rich.

** Many thanks to Dave Charlton for letting me feature his watch on the blog. **

Hi Rich, really lovely job on this piece. The before and after pics are great; it now looks set to run for another 50 years. Best – Joel

Hi Rich,

I hope that you are well and on good form. Thought I’d comment that the work you have done on the dial for this watch is remarkable. I hope that your customer Dave appreciates the effort. Best regards Adrian