It’s been a while since I’ve written about an alarm watch on the blog, so let’s have a look at this Fortis Centinela.

(Click pictures to enlarge)

Fortis was founded in 1912 in Grenchen by Walter Vogt who had developed his watchmaking skills whilst working for Eterna. Probably best known for their modern Flieger and aviation inspired chronograph watches, Fortis have an interesting vintage history which included working with English watchmaker John Harwood on the development and release of the first ever automatic watch in 1926, developing the first waterproof alarm chronometer in 1956 and the first Swiss made plastic cased watch, the Flipper, in 1967.

The watch in this post is something of a ground breaker too as it was Fortis’ first ever alarm watch. Introduced in 1954 the Centinela had a production run of just 2 years before being replaced by the less complicated, A.Schild Cal. 1475 powered Manager model, making the Centinela something of a rarity.

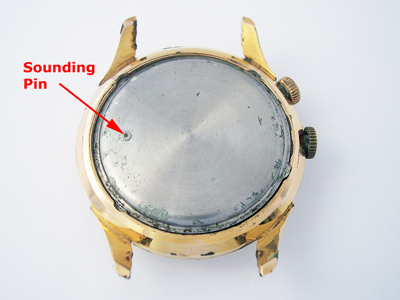

Turning the watch over the caseback is unusual as it has a number of holes in it, effectively creating an echo chamber for the alarm…

… and under the screwdown outer caseback is a sounding plate with a pin mounted on the inside which is struck by the alarm hammer, causing the plate to resonate when the alarm is ringing.

Inside the watch is a Venus cal. 230, a 21 jewel, manually wound alarm calibre with a beat rate of 18,000 bph.

The watch arrived in non-running condition and the reason was immediately obvious. As you can see above, the ratchet wheel screw had sheared off inside the barrel arbor and the ratchet wheel was rattling around inside the case.

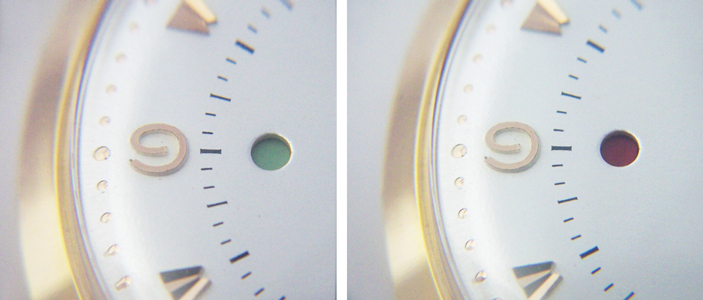

The Venus cal. 230 is an unusual alarm calibre as it only has a single mainspring barrel powering both the alarm and the going train. The calibre also has an uncommon dial aperture showing the alarm state; green for on, red for off.

In operation, the crown at 3 winds the mainspring and sets the time and the crown at 4 is used to set the alarm time and to enable/disable the alarm.

Let’s have a look at how it works…

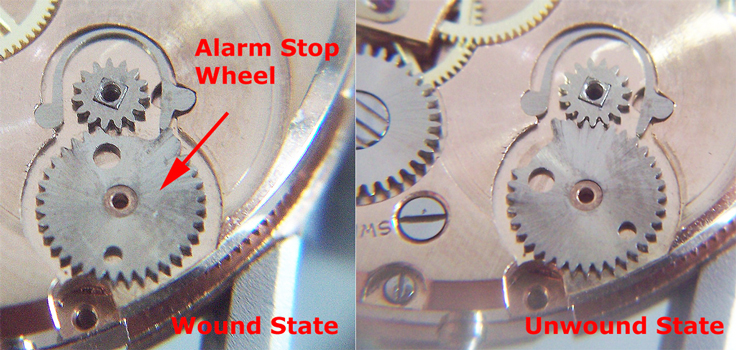

When winding the watch the first four complete revolutions of the barrel arbor set up the power source for the alarm. Under the ratchet wheel is the alarm stop wheel which controls the release of power when the alarm is triggered. When fully wound the missing teeth in the stop wheel allow the arbor/mainspring to be wound further to power the going train. The alarm stop wheel also acts as the click in a regular watch preventing the mainspring from unwinding.

When the alarm is triggered, power is released from the arbor end of the mainspring until the alarm stop wheel reaches its unwound state; a very clever way of powering the alarm as the going train continues to run while the alarm is sounding. It does however have an effect on the overall power reserve, the alarm sounds for 10 seconds which costs around 12hrs of reserve. The reserve and alarm can of course be topped up again by winding the watch.

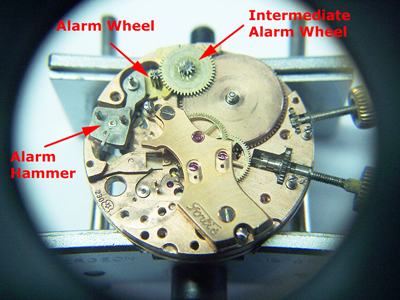

When the alarm is triggered the ratchet wheel rotates counter-clockwise, transferring power through the intermediate and alarm wheels to the alarm hammer which rocks back and forth, the two pins on top striking the pin in the sounding plate on the case.

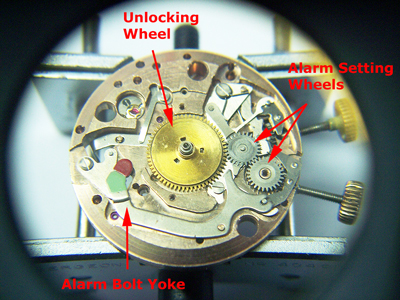

This calibre is also reasonably complicated under the dial. With the top plate removed you can see the alarm setting wheels and the green and red painted sections on the alarm bolt yoke which are visible through the dial aperture.

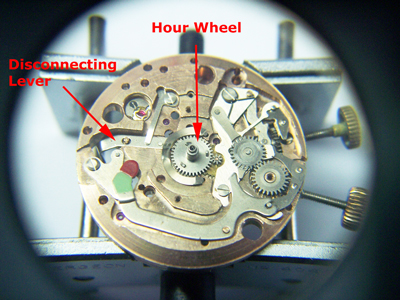

The release mechanism works the same way as the Seiko’s Bell-Matic calibre in that the unlocking wheel has three cut-outs which correspond to three raised sections on the hour wheel as seen below.

When the raised sections and the holes in the unlocking wheel align (in other words, the alarm time is reached) the hour wheel rises along with the disconnecting lever underneath, freeing the alarm hammer on the other side of the movement, releasing power from the mainspring and sounding the alarm as detailed above.

Aside from the sheared off ratchet wheel screw, the shaft of which was stuck fast inside the barrel arbor resulting in a replacement arbor being needed, the rest of the service was straight forward, so once the case had been cleaned and a new crystal fitted, the watch could be rebuilt.

At 38mm this is quite a large watch, especially for the 1950’s. It wears well and would make an interesting addition to any collection, the hard part may be finding one.

Rich.

** Many thanks to Kevin Fuller for letting me feature his watch on the blog. **