Another top quality vintage chronograph on the blog, this time from Eterna.

(Click pictures to enlarge)

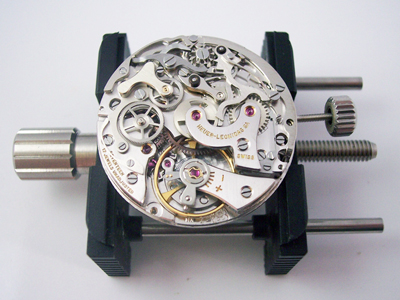

The movement inside this watch is a Valjoux Calibre 726 which is derived from one of Valjoux’s most recognised and respected calibres, the Calibre 72.

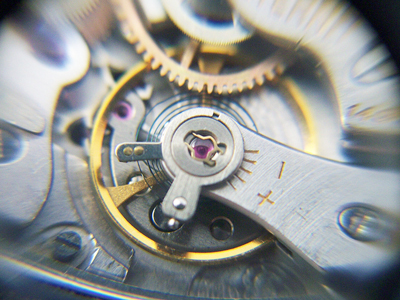

Changes were made the original Calibre 72 in 1974 to upgrade the escapement, namely decreasing the size of the balance and raising the beat rate from 18,000 to 21,600 bph. The higher beat rate increases accuracy, as a smaller, faster moving balance wheel is less affected by changes of position or knocks. Comparing the two movements you can see that the balance wheel is considerably smaller on the 726.

Although running on arrival, the watch was gaining around 5 minutes per hour, which immediately pointed to potential escapement problems.

With the caseback removed, the cause was immediately obvious. The whole movement was covered in a film of oil which had eventually found its way onto the hairspring, sticking two of the coils together. This drastically reduces the amplitude and causes a significant time gain.

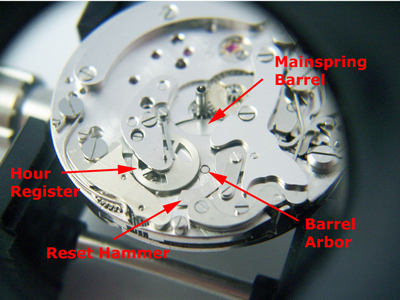

Having spotted that problem I thought that it would be plain sailing from here on in… but no. On rebuilding the watch after cleaning, the wheel train was not running freely and had a noticeable tight spot. Further investigation revealed that the mainspring barrel had been damaged at some time in the past and was no longer running true – the teeth were visibly rising and falling as it rotated.

Rather than replacing the mainspring barrel when it was damaged, the previous watchmaker had tried to ‘work around’ the problem by bending the mainplate in several places to give the barrel more room – a big mistake!

As you can see in the picture below, the chronograph hour register and its reset hammer are located on the dial side of the movement opposite the barrel, so consequently, bending the mainplate had an effect on these parts too.

The tolerances for these parts is minimal even with a perfect mainplate, so it was no surprise that the reset hammer was dragging on the mainplate and the hour register was also binding. Not good.

After ordering a new mainspring barrel and mainspring, the required ‘adjustments’ could be made to the mainplate. Obviously, with the parts all in place it isn’t possible to make the required tweaks, so the watch had to be disassembled each time, making it a time consuming operation.

My patience paid off and the problems were resolved eventually, so with everything working again I could complete the rest of the rebuild.

From a cosmetic point of the view the watch was in pretty good shape, but the lume had deteriorated over the years. The dial also had a thin film of oil over it and several marks in the subdials. With careful cleaning and a relume things were much improved, but I couldn’t do anything about the scratches in the hour subdial.

The hands were relumed too and the case cleaned before reassembly. Quite a bit of effort to get this one back in order, but well worth it I’m sure you’ll agree.

Rich.

** Many thanks to Simon Fox for letting me feature his watch on the blog. **