Like the Philip Caribbean 1500 I wrote about a couple of months ago, this Gruen Precision is another diver that you won’t see very often.

(Click pictures to enlarge)

Capitalising on a patent granted for an improved safety pinion, Dietrich Gruen founded the Columbus Watch Manufacturing Company in Ohio, USA in 1876. Using movements imported from Switzerland, Gruen produced good quality pocket watches for the American market, and went on to introduce the first stem-wind pocket watch into the USA. His watches proved popular, and in less than a decade he decided to take on new partners and move to larger facilities, after which the company quickly grew to 150 employees and were producing 300 watches per day.

However, all was not well behind the scenes and after a series of disagreements with the other partners, Gruen and his son (Fred) left the company in 1894 and formed the partnership “D. Gruen & Son”.

After a successful period creating watches for the US military, in 1917 the company moved to a new custom built factory in Cincinnati named “Time Hill”. Between 1921 and 1958 they produced the majority of the watches that Gruen are famous for; the Veri-thin range of pocket and wristwatches, the rectangular Quadron range, and undoubtedly their biggest success, the Curvex.

Introduced in the 1935, the Curvex was the first watch with a curved movement to better match the profile of the wrist.

After the death of Fred Gruen in 1945, the company began to lose focus and despite achieving its highest sales figures to date, it was sold by the family in 1953. The company then entered a turbulent 5 year period which saw high level mismanagement, and the legal battles between the board members and stock holders often made newspaper headlines. The company changed ownership several times in quick succession and was slowly stripped of its assets, the huge debts eventually forced the company to lay off employees and close down manufacturing facilities – incredibly, all the factory records prior to 1958 were considered ‘no longer of any use’ and were destroyed.

The company eventually found a new owner based in New York and mechanical watches were manufactured again under the Gruen name. As well as ‘Precision’ dress watches, several diver’s watches also were produced. Here are a few more examples.

Unfortunately, Gruen’s ‘phoenix from the ashes’ story ends before it really got started as the company was swept aside by the quartz revolution and was forced to close its doors for the final time in 1976.

The calibre inside the watch in this post is a Gruen cal. 560 RSS. Although Gruen did produce their own calibres, by the time this watch was produced all the manufacturing facilities had been sold off and Gruen were sourcing calibres from other manufacturers and re-branding them as their own. The base caliber of the 560 RSS is a 17 jewel Bidlingmaier ebauche, with an added automatic winding mechanism (a 23 jewel version was also available).

Although running on arrival it wasn’t possible to set the time, and cosmetically it was in pretty rough shape with poor lume throughout. Though it’s not immediately obvious from the pictures above, the lugs had also been bent inwards at some point – in all likelihood by some ‘genius’ with a pair of pliers as the case still had deep gouges on the outside of the lugs… correctly sized spring bars must have been in short supply that day. 🙁

As the damage was pretty bad, the case was sent out for restoration while I completed the rest of the work.

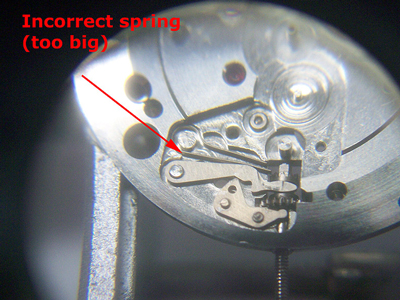

During the movement service the problem with the keyless works was quickly uncovered; a click spring had been fitted which was way too big, preventing the stem from being pulled all the way out to set the time.

A click spring of the right size quickly put things right and the rest of the service was straight forward, so it was on to the cosmetic work.

As is clear in the first picture, the lume had fallen out of the hands and had deteriorated badly on the 3, 6 ,9 and 12 hour markers (the other hour markers are painted triangles). Ordinarily all traces of the old lume would be removed first before re-luming, which was no problem with the hands, but on the dial the lume on the hour markers was rock hard. So, rather than risk damaging the dial or the painted markers underneath the lume, a new layer of vintage cream lume was applied on top of the old. Not ideal, but given the situation (ie. the chances of finding a replacement dial being zero!), it was the right choice.

With both the servicing and cosmetic work completed, and the case back from the restorer, the watch could finally be rebuilt. However, that isn’t the end of the story as an unexpected problem occurred during testing.

As part of the post-service checks, every automatic watch is tested on a winding machine to ensure that the winding and calendar mechanisms are working correctly. During this testing, the Gruen kept stopping at irregular intervals, and on opening the watch I found that the winding rotor was jammed. It only took the slightest nudge to get it started again, but it hinted at a bigger problem with the automatic winding mechanism.

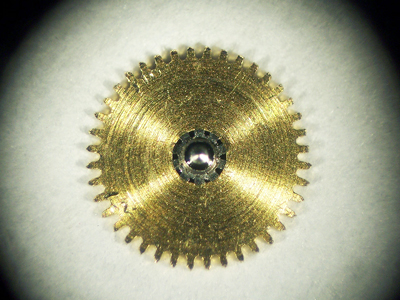

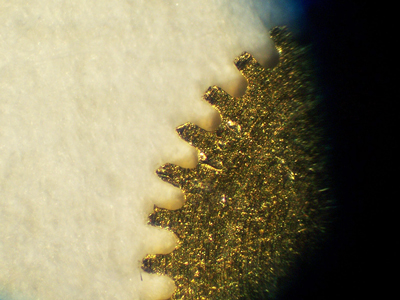

It’s not uncommon to see some wear in an automatic winding mechanism, especially after decades of daily use, but in this case the wear was not obvious without magnification. The picture below shows one of the transfer wheels at 30 times magnification and as you can see, the tops of the teeth in the top right quadrant have worn away.

At 90 times magnification, you can see that some teeth were in particularly poor shape, and some even had grooves worn into them which were causing the rotor to jam.

As parts for this calibre are long discontinued, I tried to reshape the worst of the teeth with a cutting broach to at least get the watch up and running until a donor mechanism could be found. Despite several attempts it didn’t work as the wheel was just too worn, and the rotor continued to jam while on the winding machine.

Thankfully a donor movement was quickly found in the US and arrived after a couple of weeks. The winding mechanism on the donor proved to be in better condition than the original, so the whole mechanism was stripped, cleaned, lubricated and installed to finally finish the job.

Rich.

** Many thanks to Daniel Spiegel for letting me feature his watch on the blog, and to Paul McRae for his work on the case. **

Amazing job Rich. And nice to read.

Well done!

Wow! Great work on getting it up and running again.

I love the shape of the hands on this one! And the bracelet is just great!

What is the size of this thing?

Thanks!

I didn’t measure the case I’m afraid, but it isn’t one of those massive divers. I’d say it’s around 39-40mm in diameter, so very wearable.

Rich.