Here is a watch that you don’t see every day, a Zenith Surf.

(Click pictures to enlarge)

Zenith dates back to 1865 when 22 year old Georges Favre-Jacot started the company in Le Locle, Switzerland. At that time, most watchmaking tasks were performed by individual watchmakers working in their own homes, but Favre-Jacot changed all that by bringing all the disciplines together under one roof where they could work together, increasing production rates, and improving quality.

The concept certainly worked and by 1875 the company employed over 1000 people producing pocket watches, pendulum clocks and counter instruments. By 1922, the company had produced 2 million timepieces.

Although Zenith have produced more than 50 calibres and won over 1500 watch industry awards, they are probably most famous for creating the legendary “El Primero” chronograph calibre. It was (arguably!) the first chronograph caliber with automatic winding, and was the only mechanical chronograph with a beat rate of 36,000bph, capable of measuring time intervals to an accuracy of 1/10 of a second. It was, and still is a fine piece of engineering, and is still in production today.

The watch in this post arrived in a non-running state as water had found its way inside the case at some point, and judging by the condition of the movement, it must have been quite some time ago. You can see in the following picture rusted parts and signs of dried water on the winding rotor and caseback. Never what you want to see when you open a watch!

The water had also affected the dial and hands, staining the dial, and damaging the lume in the hands.

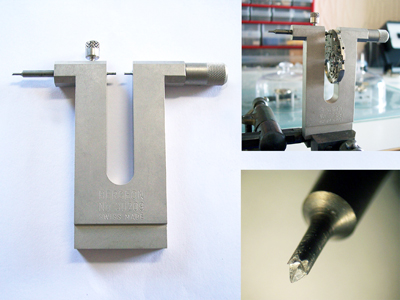

When parts have rusted, care has to be taken during disassembly as it is very easy to break the head off a rusted screw, leaving the threaded shaft behind. If the threaded shaft is rusted in place it can be very difficult to remove even with the right tool for the job; Bergeon’s broken screw extractor.

The tool is mounted in a suitable vice and the broken screw in the plate (or bridge) is aligned with the two pins at the top of the tool. These pins are made from hardened steel and have serrated teeth (bottom inset) which cut into the shaft of the broken screw. The pins are screwed firmly into place holding the shaft securely from both sides (top inset) and the plate is then rotated by hand until the shaft is screwed out of the plate.

When a watch is water damaged, it is often a trade off between the amount of time needed to clean up and refinish rusted parts, and the cost and availability of replacing them. Although water had found its way right through this watch, only superficial rusting had occurred on some of the parts so the cleanup was relatively straight forward, and only the two rusted bridge screws for the automatic winding mechanism had to be replaced.

With the movement all cleaned up and running again, the stain was carefully removed from the dial, the hands were relumed, and the case and bracelet cleaned. Here is the result.

Rich.

** Many thanks to Francois Canters for letting me feature his watch on the blog. **

Please note that the beat rate on this watch, with the Cal. 2572PC, is 28,000bph.

Hello. I have same similar watch gifted to me. Question..can you manually wind your watch ? I can’t seem to turn crown. Runs by moving wrist. Thanks for any input.

Hi Roberto,

Yes, you should be able to manually wind your watch. If that’s no longer possible it could be that parts in the automatic winding mechanism are worn (the mechanism is designed to ‘slip’ when manually wound), or the watch may be due for a service.

I hope that helps!

Rich.